Date:2022-10-25

What is an Automotive-grade Inductor?

Let's dive straight in. An automotive-grade inductor, in a nutshell, is an inductor product that meets the AEC-Q200 standard; and it’s produced in a factory that adheres to the ISO/TS16949 standard quality management system certification.

To elaborate, let’s delve into a specialized term: automotive-grade. Let's start with the acronym: AEC-Q. AEC stands for "Automotive Electronics Council," a committee established by Chrysler, Ford, and General Motors to create a set of common standards for part qualification and quality systems. AEC, a conglomerate of major automotive manufacturers and major American component manufacturers, aims to standardize specifications focused on the reliability and recognized standards of automotive electronic components. The AEC has established quality control standards. [AEC-Q100] targets integrated circuit stress test certification, the standard for discrete devices is [AEC-Q101], for LEDs is [AEC-Q102], and for passive component design is [AEC-Q200].

AEC has set quality control standards and, because components that comply with AEC specifications can be adopted by the aforementioned three automakers simultaneously, it also encourages component manufacturers to exchange product feature data. This has facilitated the implementation of automotive component universality and laid the foundation for rapid growth in the automotive component market. AEC primarily targets vehicular applications, automotive components, and standardizes quality management control standards for automotive electronics, enhancing their stability and standardization. The most common automotive electronic component test standards by AEC are AEC-Q100- (001~012), AEC-Q101, and AEC-Q200.

The validation process for AEC-Q200 is very complex, time-consuming, and energy-intensive. Automotive-grade inductors, and other automotive-grade passive components, not only have to comply with stricter operating temperature environments, such as -40~+155 degrees Celsius, but AEC-Q200 certification also requires passing high-intensity mechanical vibrations, ultra-long life operation, high-precision excellent electrical characteristics, very strong solderability, terminal strength, resistance to high-intensity mechanical impact, resistance to PCB board bending strength, passing electrostatic discharge testing, high humidity salinity testing, high-temperature resistance testing, thermal shock testing, reflow soldering testing, leakage current withstand voltage testing, and so on. An automotive-grade power inductor, to meet AEC-Q200 certification, needs to go through dozens of stringent testing standards, and each standard requires a long time to be spent, such as life testing and high humidity salinity testing, which require thousands of hours of test time.

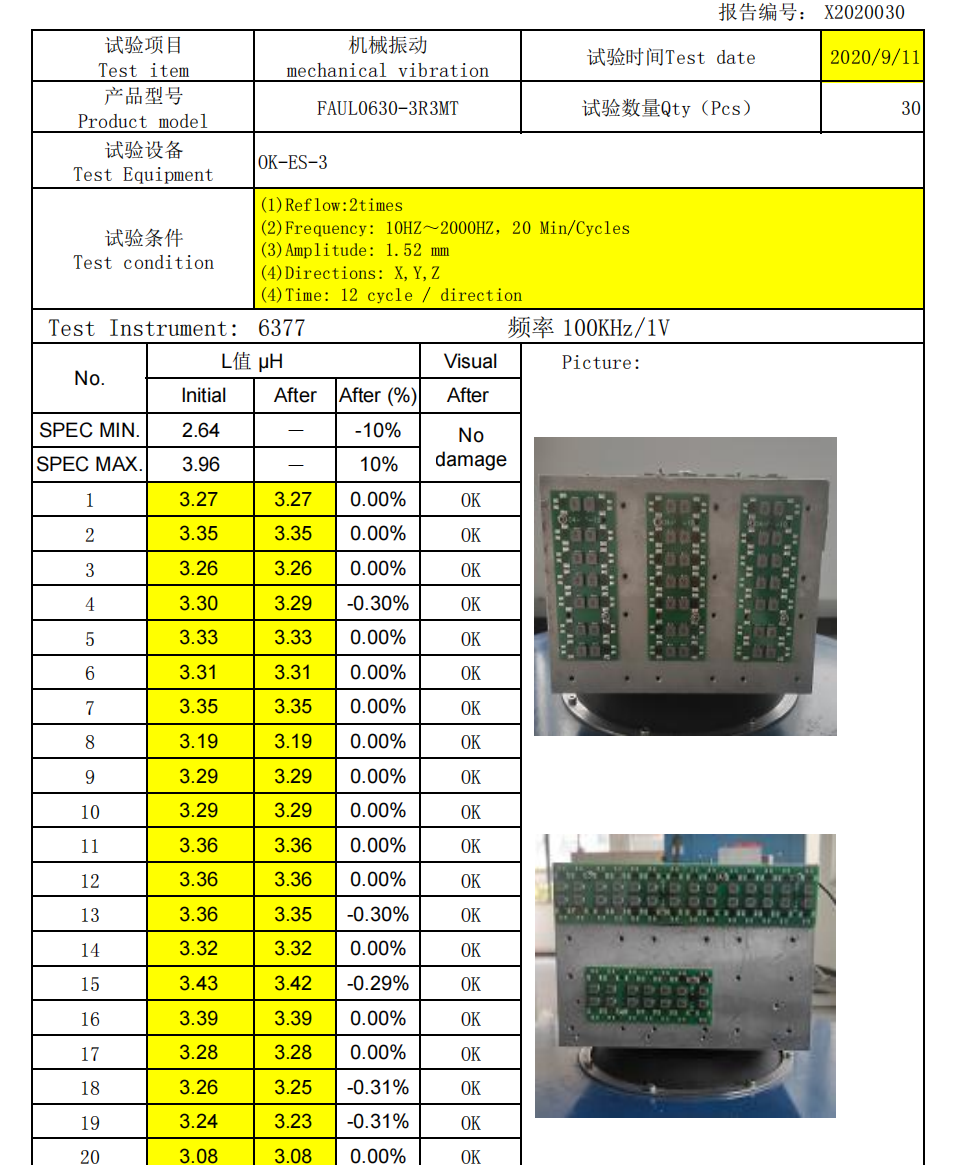

In one brand's mechanical vibration testing...

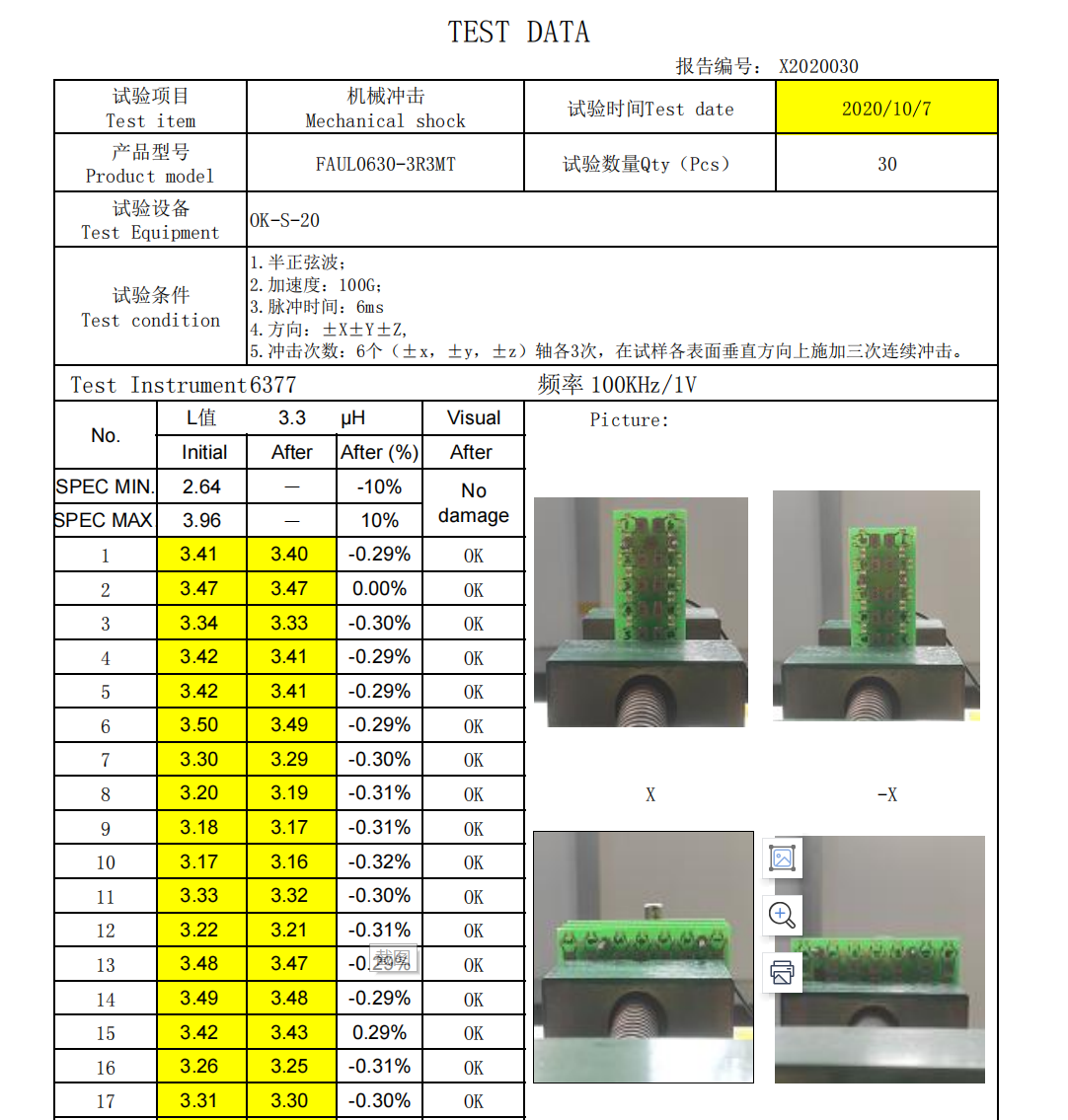

Mechanical shock:

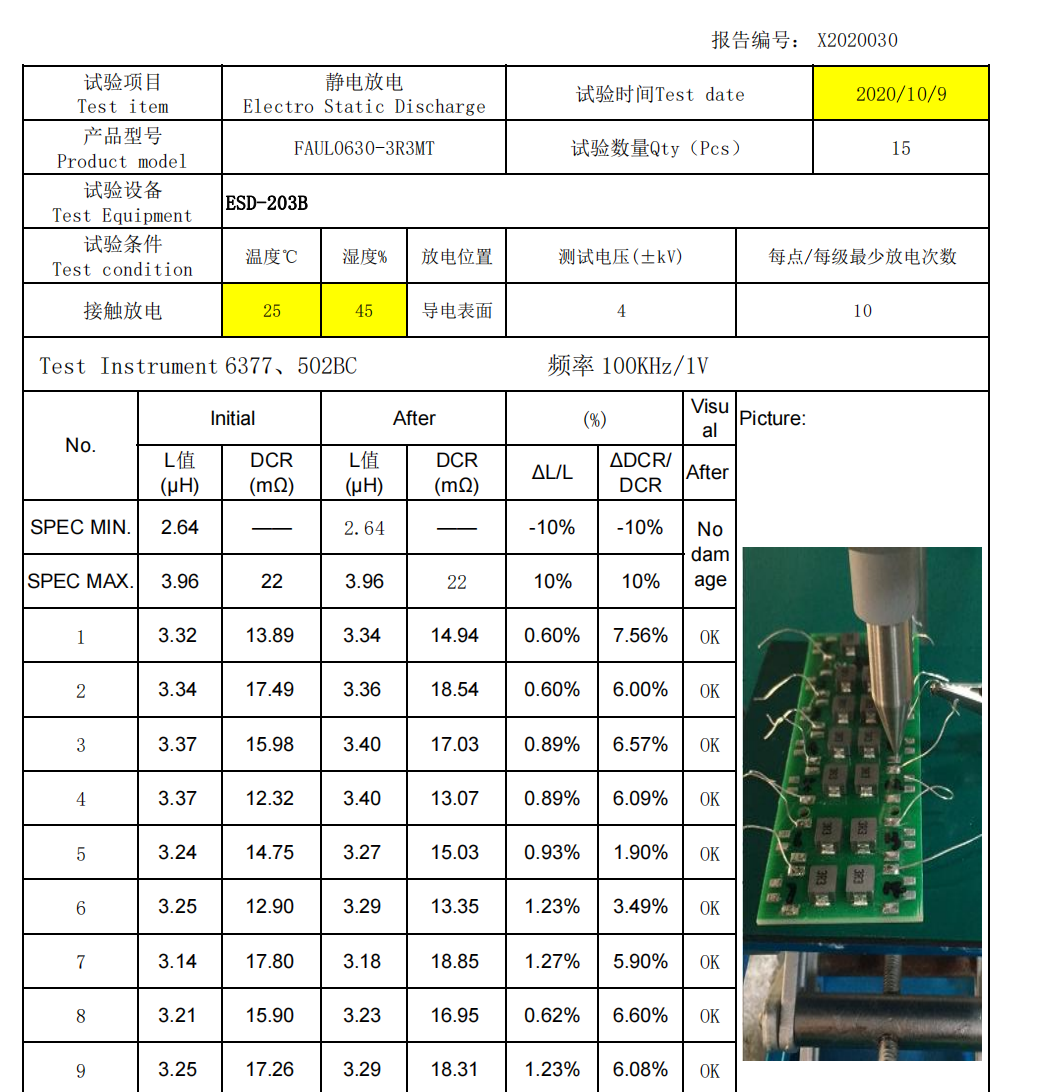

Anti static testing: